- Online pavilions:

- Veterinary medicines

- Veterinary raw materials

- Other

- Asia

- America

- medical instruments

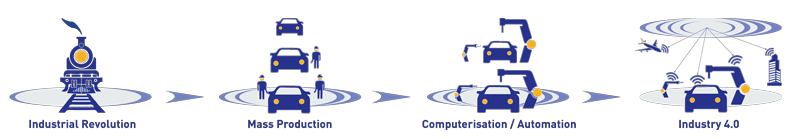

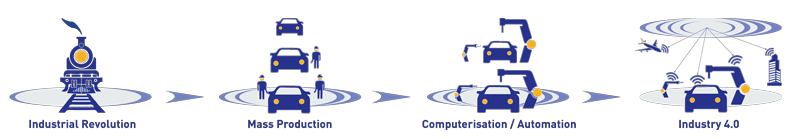

News briefing: A lot has been written on Big Data and the Industrial Internet of Things (IIot), also known as Industry 4.0, and how it’s changing the face of industries like transportation and logistics, manufacturing, aviation, and oil and gas production. But not so mu

Technology writer, Alasdair Gilchrist, describes Industry 4.0 as the convergence of people, physical systems, and data within an industrial process to increase quality, productivity and profit by using the power of advanced data analytics. Pharma 4.0 can be defined in the same way.

Why 4.0? It’s a play on two things:

Beyond the ever-present need for pharmaceutical manufacturers to remain competitive in a growing marketplace of increasing complexity is regulators’ increasing push for continuous product monitoring. In the past, regulators accepted an annual product quality review as adequate (although not necessarily ideal), but there is a growing expectation that manufacturers will perform such reviews much more frequently than annually. Pharma 4.0 technology allows for continuous, real-time monitoring of manufacturing processes so any drift away from specified parameters can be predicted and rectified before it turns into a deviation, avoiding the associated down time and loss of product.

Increasing pressure on R&D departments to develop not only new products faster than in the past, but also more personalised therapies, is another factor driving the move towards Pharma 4.0, but that’s a post for another day.

A pharmaceutical manufacturing plant set up according to Pharma 4.0 principles is made up of machines, equipment and computers, but rather than the typical automated process control (APC) elements that have been standard since the late nineties, all the machines and equipment – even individual components within them – are fitted with multiple sensors that are constantly monitoring every aspect of the process and even their own wear and tear. These ‘self-aware’ components can report on their own condition, indicate how much useful life they have left, and predict when they’re likely to fail. Imagine the savings in down time that such a capability could deliver.

An single online tablet inspection system generates huge volumes of data – up to 24 terabytes a year. By way of contrast, the whole of United Airlines ‘only’ generates around 9 terabytes a year. To reap the rewards that Pharma 4.0 offers, all that data needs to be processed using some of the advanced analytical tools that have emerged as a result of the big data evolution. Artificial Intelligence (AI) will play a growing role in data analytics.

Big data analytics draws data from sources that have traditionally been disconnected from one another, and looks for relationships and trends that were previously undetectable. For example, data from the online inspection system described above can be combined with that from equipment maintenance and engineering systems to streamline maintenance schedules; combining production data with that from sales and dispatch systems can streamline production planning. Enterprise Resource Planning tools can already do some of this but they’re necessarily working with smaller data sets than a Pharma 4.0 plant would generate so their conclusions and recommendations are comparatively less valid.

There are fewer operators needed on a Pharma 4.0 production line and the jobs are highly skilled. Some commentators are calling for ‘Data Scientists’ to staff these operations, but as Trevor Schoerie, Managing Director of PharmOut, explains:

In a Pharma 4.0 environment, a Data Scientist is not an individual person – it has to be a team or a consultant (QikSolve), as there are so many different skills required. You need to understand the technologies like Hadoop, Hive, and Pig – these process all the big data. Then you need to understand statistics and related programs, like open-source ‘R’, or proprietary systems like Minitab, SAS or Mathworks. Then, of course, you have to know how to interpret the data and statistics; to create data visualisation using tools like Microsoft’s Power BI; and to make decisions based on the data.

In addition to their technical skills, staff need industry knowledge and an in-depth understanding of their facility and the production processes. Data quality will improve with increasing automation, but it will be some time yet before all the data needed is delivered in a clean, ready-to-use format. So staff will spend time preparing data for analysis.

Current automated process control (APC) strategies improved quality oversight when they were introduced in the nineties, but they are, by nature, reactive. They can only tell you what’s gone wrong, not what’s about to go wrong and within what timeframe. But Pharma 4.0 is about more than just process control. By increasing the amount of monitoring throughout the production cycle – not just on the production line – Pharma 4.0 offers predictive analysis and a world of other business insights that are currently unavailable because they’re buried in unstructured, dispersed, incomplete data.

The cost of fitting out a pharmaceutical manufacturing site according to Pharma 4.0 principles has been cited as a barrier, but the cost will be quickly offset by increases in productivity and a reduction in down time and waste. Gilchrist speaks of ‘the power of 1%’, which refers to the idea that an industry only needs to decrease operational costs / inefficiency by just 1% by using Industry 4.0 principles to realise significant savings. He gives the following examples:

Finding enough adequately skilled staff to run the analytics is also proving difficult, as universities struggle to predict what skills industry will require in coming years. Yet it’s clear already that advanced analytical skills will continue to be in demand for the foreseeable future.

Security is another concern. Pharma 4.0 means connecting thousands of individual devices – sensors, actuators and networks – and each connection represents a point of weakness from a system security perspective. To reap the benefits of Pharma 4.0 and mitigate the security risks, manufacturers will need to invest in skilled security staff.

Trevor Schoerie refers to ‘the inertia of big committees’ embedded in large multinationals as another barrier to adopting a Pharma 4.0 approach and warns that disruptions have seldom come from within an industry. ‘Look at ABNB, Uber, or Telsa. They’re both from outside the industries they’re impacting yet are changing the game. There’s no going back once developments like these have shown their worth. You either get on board or get left behind.’

Although pharma has typically been a risk-averse industry, it has the support of regulators in moving towards the Pharma 4.0 approach. The barriers will fall, in time, and Pharma 4.0 will become the new standard.